|

|

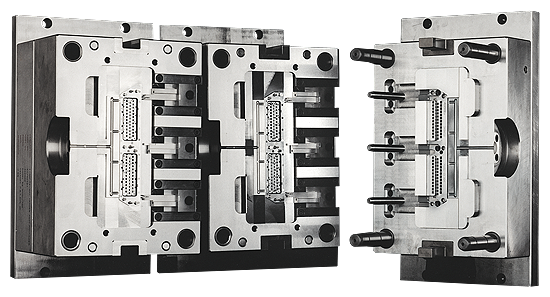

| 1 Impression Tool Insert Moulded Via Rotating Table - TO PRODUCE A 72 WAY HEADER |

|

|

|

|

|

| This single impression tool operates in a vertical moulding machine. Two identical ejection half assemblies are bolted to the machine's rotary table opposed at 180°. The contact inserts are assembled into one half whilst the moulding process continues on the other half. When this process is completed the table indexes 180° to enable procedures to be repeated in a continuous operation. |

| Dimensions |

346 x 246 x 350mm |

| Weight |

940 Kilos |

| Material |

30% GF PBT |

| Press |

Engel ES600H/100 |

|

|

|

|